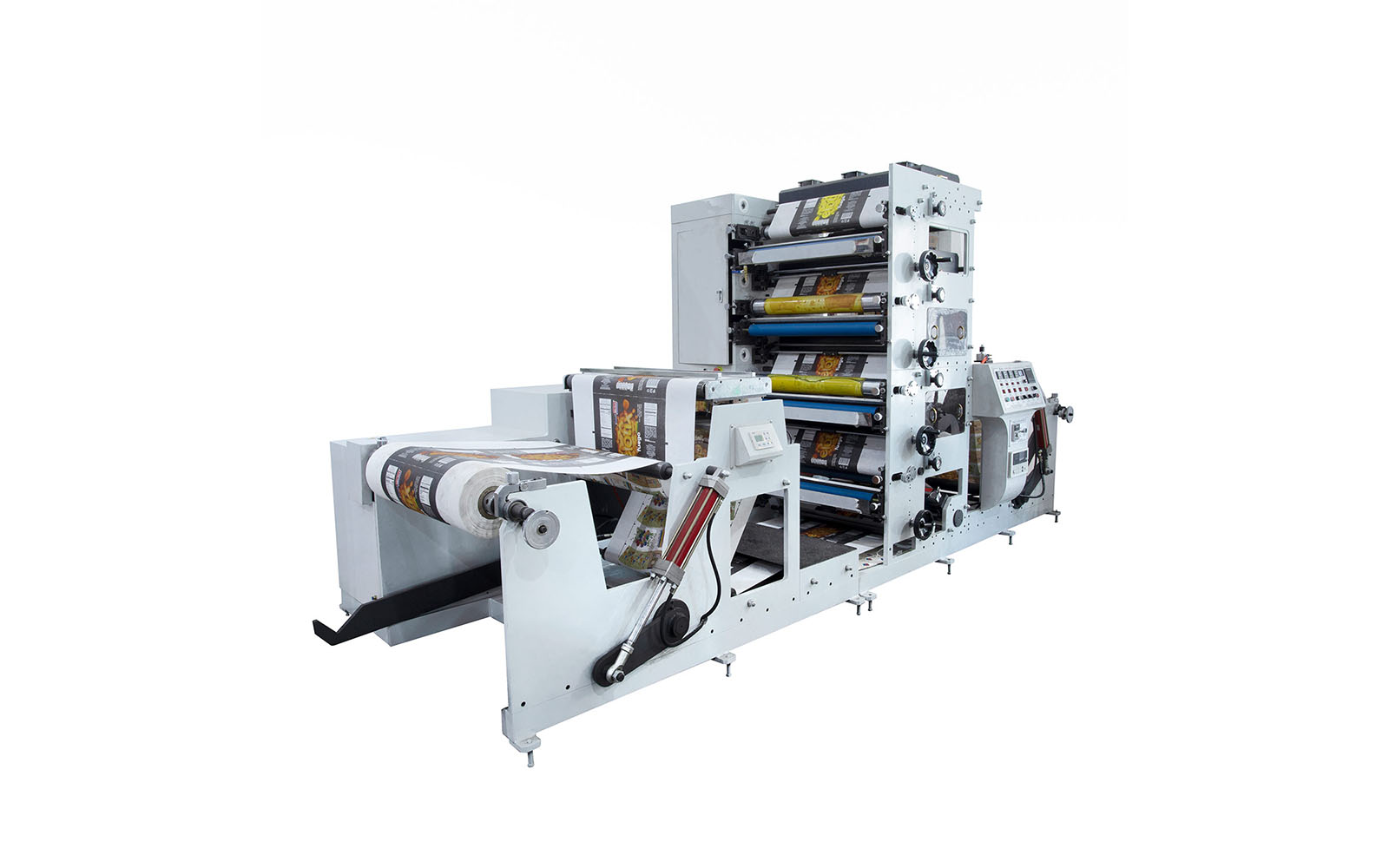

1.Main technical parameters:

Print speed | 60m/min | |

Print color number | 4 colors | |

Feeding width | 650mm | 850mm |

Max unwind diameter | 1000mm | |

Max rewind diameter | 1000mm | |

Max print size | 180-380mm | |

Overprint precision | ±0.15mm | |

voltage | 380V 3phase 4wire 50hz | |

Total power | 30kw | 36kw |

Total pressure | 0.5Mp | 0.6Mp |

Weight | 3800KG | 4500KG |

Outline dimensions | 4500*1600*2250mm | 4500*1800*2250mm |

2.Description:

þCeramic anilox cylinder to transfer the ink

þAutomatic magnetic powder brake controller for unwinding & rewinding

þTension controller for unwinding

þTension controller for rewinding

þPrinting unit: 360°Plate-adjustment

þIR dryer for each printing unit.

þWeb guide system in the machine

þUnwind use separate frame

þUnwind and rewinding adopt auto loading/unloading system

þThe ink rollers will be separated from the printing roller, and keep running, when machine stopped.

þFrequency converter for speed controlling

þ2 plate cylinders and 1 ceramic anilox rollers

þFeed paper form roll material, print, dry automatically by IR and rewinding completed in one time.

þIt is an ideal machine for printing trade invoice and top-grade adhesive label, PVC, paper cup, plastic and aluminium foil.

3.Optional parts:

Anilox cylinder specification made by request;

Plate cylinder specification made by request;

Double sides printing of material-reversing device;

Rotary die cutting set in the machine

Slitting set

Sheet conveyor

Cold laminating

Cold stamping

Video inspection system

Corona treatment device

UV dryer

Delam Relam

PLC Control

4.Machine Detailed Pictures:

|

|

Web guide | Corona treatment |

|

|

Rotary die cutter | Tension controller |

|

|

Control panel | IR dryer |

|

|

unwind | Print adjust wheel |