1.Parameters:

1.Parameters:

Descriptions | Parameters |

Max machine speed(servo motor) | 150m/minute |

Led UV dryer speed | 150m/minute |

Hot dryer speed | 150m/minute |

Printing color number | 8 color |

Material thickness | 30-300g |

Max width of paper | 350/450mm |

Max printing wide | 350/450mm |

Max.die cutteing width | 350/450mm |

Plate thickness | 1.14mm/1.7mm (According to you request) |

Max.printer perimeter | 190.5mm-571.5mm |

Tape thickness | 0.38mm |

Max unwinding diameter | 800mm |

Max rewinding diameter | 600mm |

Precision of overprint | ±0.1mm |

Voltage | 380V 3phase 4 wire 50hz |

Overall dimension | 10(L)×1.9/2.0(W)×1.3(H)m |

Machine weight | About 10000kg/13000kg |

2.Working Principles & Application Areas:

Unwinding →Web Guiding→printing→Drying → Rewinding

It can be printed on carbonless paper, thermal paper, aluminized paper, coated paper, cardboard, copy paper, self-adhesive,BOPP, PET plastic film and other materials. It can be widely used in printing fields such as labels, multi-layer labels, tissue paper, plastic films, paper cups, cartons, food packaging bags, wrapping paper, etc.

3.Main Feature:

1.Servo motor controller for unwinding .

2.Servo motor controller for rewinding .

3.Paper breaking stop device.

4.Printing unit: 360°Plate-adjustment.

5.Paper guide roller adopted high hardness anodized treatment,Ball screw electric actuator,Adopted ultrasonic sensors for web guide system.

6. One pcs 3 inch air shaft for unwinding

7.Two pcs 3 inch air shaft for rewind

8.Each printing group has a touch screen, and then all the screens are placed on the switch and distributed to each small screen through the switch.

9. Both LED UV dryer and hot air for each printing unit,8 color.

10.Each printer unit single servo motor,register,pre-register,re-register

11.A video camera

12.Three set plate cylinder

13.One set ceramics anilox roller

14.Extra ceramics single corona

15.Extra Dlema relam

16.Extra turn bar (can printer double side)

17.Extra Cold stamping(servo motor control)

18.Extra laminating

19.One station die cutter (servo motor control)

20.Waste Remover

21.8 set round knife slitter

22.BST web guide system

23.The thickness of the wall plate is 30mm

24.Each printer unit water cooling roller ,a chiller

4.Machine include details pictures for reference:

| |

Unwind part | Rewind part |

|  |

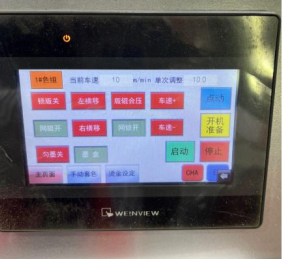

PLC touch screen | |

|  |

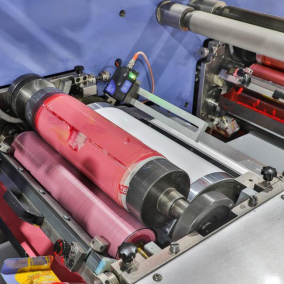

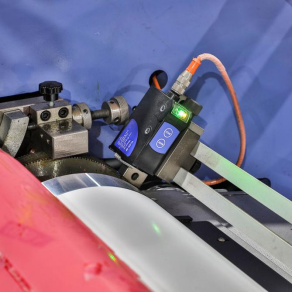

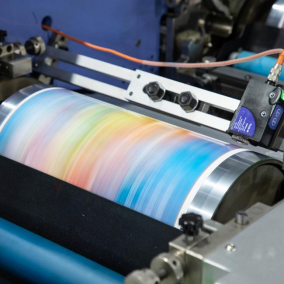

Printing unit | Color sensor(register) |

|

|

Pre-register | Servo motor |

|  |

Water cooling roller | Chiller |

|

|

Video inspection system | |

|

|

Turn bar (Can printer Double sides ) | Single side ceramics corona |

|

|

Delam Relam | |

| |

Cold stamping | Cold laminating |

|  |

Die cutter station | Slitting |