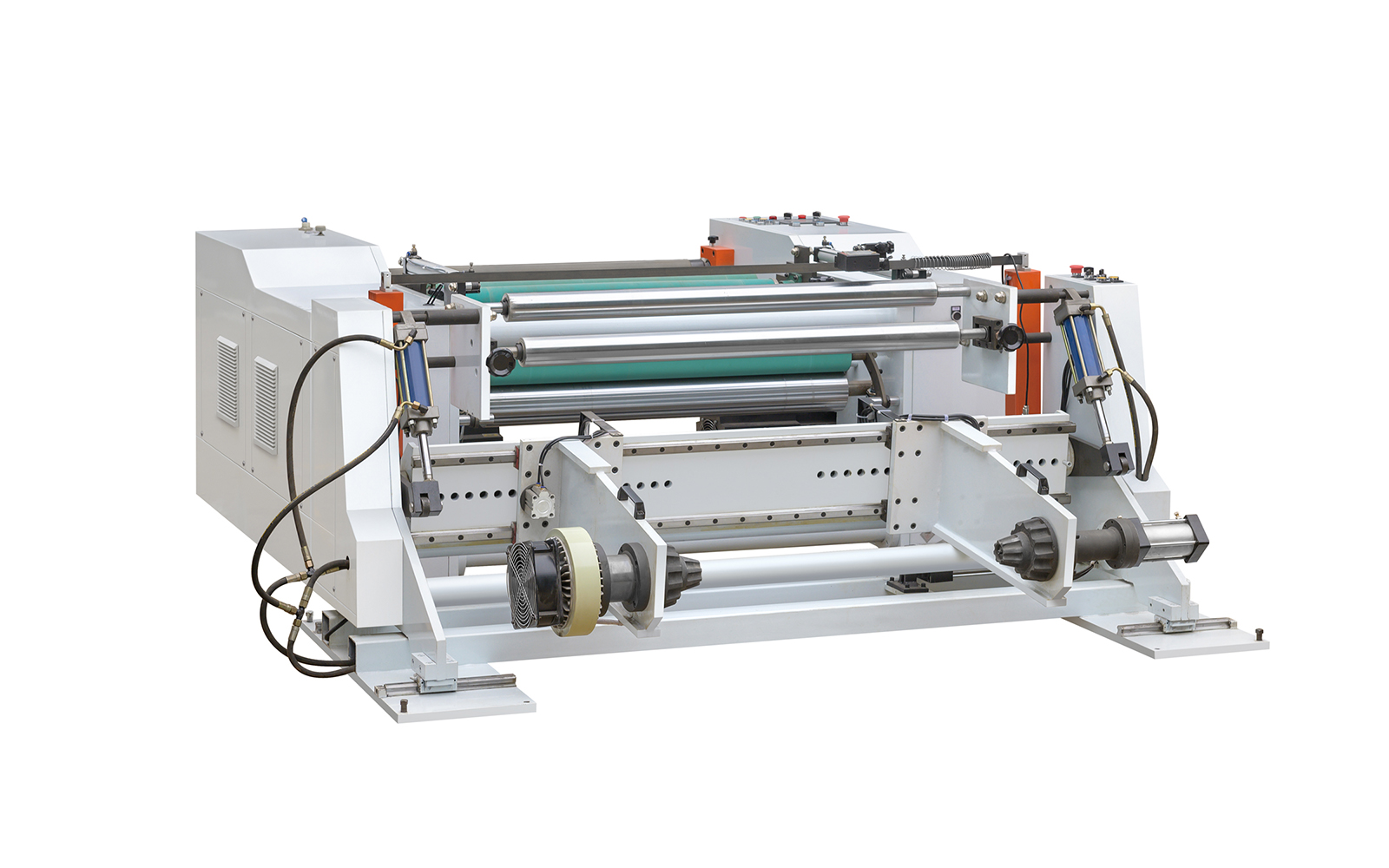

1.Main Technical Parameters:

| Max web width | 1100/1300mm |

Max rewind diameter | 600mm |

Max unwind diameter | 800mm |

Min slitting width | 25mm |

Power voltage | 380V |

Cutting precision | 0.2mm |

Total power | 5/7.5kw |

Slitting speed | 200m/min |

Machine weight | 2500/3000kg |

Description:

þThe main body uses HT280 casting plate/q345 steel plate computer CNC processing synthesis.

þThe main pressure roller diameter 105mm rubber roller core uses the surface of aluminum roller and rubber roller.

þThe diameter of the guide roller is 90mm Directors. The guidelines are made of aluminum roller inside and outside the same precision processing. The surface of the guide is oxidized. The surface is smoother, more stable, and higher accuracy when cutting.

þHost driving mode: Single motor synchronization of the same axis driver.

Main motor: 5.5 (level 6) KW, Inovance 7.5kW frequency conversion speed adjustment.

þMain control computer program: centralized control of Mitsubishi PLC, (Weinview) touch the screen human machine interface, automatically calculates taper tension control technology.

þPutting the roll method: split or courses.

þThe whole machine transmission mode: synchronize with transmission.

þAutomatic correction unit: The automatic correction of the servo motor ultrasonic simulation computer (domestically produced).

þThe feed shaft: 3inch board air shaft 2pcs for rewind,unwind use 3 inch air shaft.

þEquipment method: Adopt air pressure automatic rising (800kg).

þPut the tension with unwind magnetic powder brakes: 100N.M.

þRewind tension uses a magnetic powder clutch: 100 N.M.

Machine Detailed Pictures:

|

|

Web guide controller | Round knife |

|

|

Web guide sensor | Rewind roll |